The Ultimate Aluminum Casting Handbook: Step-by-Step Recommendations for Success

Safety And Security Preventative Measures for Aluminum Casting

In addition, preserving a neat office devoid of mess can prevent tripping threats and assist in the movement of personnel throughout casting procedures. aluminum casting illinois. Appropriate training in handling liquified light weight aluminum and operating casting devices is vital to lessen the threat of accidents and injuries. Routine tools maintenance and evaluation should be conducted to recognize and remedy any kind of possible safety threats promptly

Establishing Up Your Light Weight Aluminum Casting Work Area

Developing a effective and safe work space for light weight aluminum spreading is critical for making sure smooth procedures and reducing possible hazards. Prior to setting up your office, make sure that it is well-ventilated to protect against the build-up of harmful fumes created throughout the spreading procedure. It is vital to have actually an assigned location for each phase of the casting process, such as pattern making, mold prep work, and steel pouring, to enhance workflow and prevent cross-contamination.

Choosing the Right Aluminum Alloy

To make certain ideal casting leads to your efficient and safety-focused work space, picking the appropriate light weight aluminum alloy is extremely important. Various aluminum alloys supply different qualities such as strength, sturdiness, heat resistance, and machinability. The selection of alloy relies on the details requirements of your spreading project.

One frequently used aluminum alloy for casting is A356. This alloy exhibits exceptional fluidity, making it perfect for detailed castings with thin walls. A356 additionally has great corrosion resistance and mechanical homes, making it appropriate for a large array of applications.

If higher strength is needed, 7075 light weight aluminum alloy is a popular option. Known for its high strength-to-weight ratio, 7075 is usually made use of in applications where toughness is vital, such as aerospace components.

For projects that include high-temperature environments, 319 aluminum alloy is an excellent choice due to its superior thermal conductivity and resistance to thermal splitting.

Step-by-Step Aluminum Spreading Process

Beginning the aluminum casting process involves meticulous preparation and adherence to an accurate series of actions to guarantee the production of high-grade castings. helpful resources The initial action is pattern development, where a replica of the end product is made from plastic, wood, or metal. This pattern is after that utilized to create the mold, which can be made from materials like sand or plaster. As soon as the mold and mildew is prepared, it is time to melt the light weight aluminum in a furnace at temperatures exceeding 1200 ° F.

After reaching the preferred temperature, the liquified light weight aluminum is put right into the mold and mildew dental caries. This step requires caution and precision to avoid defects in the final casting.

Throughout the entire procedure, cautious tracking and quality control steps need to be carried out to make certain the last aluminum spreading meets the required specifications and requirements.

Tips for Developing Your Spreading Technique

In refining your aluminum casting method, meticulous focus to information and adherence to specific steps are paramount to making sure the production of high-quality castings. One critical suggestion for developing your casting method is to carefully prepare the mold and mildew and guarantee it is clean and appropriately coated with a launch her comment is here representative to assist in the very easy elimination of the spreading. Additionally, keeping the light weight aluminum at the right temperature level throughout the spreading process is vital for accomplishing ideal flow and decreasing the risk of flaws. An additional tip is to put the liquified aluminum slowly and steadily right into the mold and mildew to stop air entrapment and make certain a smooth fill. It is additionally important to enable enough time for the light weight aluminum to solidify totally prior to eliminating the spreading from the mold. Inspecting the spreading for any blemishes and making needed changes to the process will certainly assist you enhance and excellent your light weight aluminum casting method over time.

Final Thought

To conclude, following correct safety and security precautions, establishing an ideal work area, selecting the click to read correct aluminum alloy, and vigilantly adhering to the step-by-step spreading process are essential for successful light weight aluminum casting. By taking note of these crucial elements and incorporating ideas to improve your technique, you can achieve superb cause your light weight aluminum casting jobs.

From safety preventative measures to developing spreading strategies, this handbook serves as a beacon of expertise for those venturing right into the world of light weight aluminum spreading.

Beginning the aluminum casting procedure entails precise preparation and adherence to a specific collection of actions to make sure the production of high-grade castings.In refining your aluminum casting technique, careful attention to detail and adherence to specific actions are paramount to guaranteeing the manufacturing of top notch castings. One critical suggestion for refining your casting technique is to thoroughly prepare the mold and mildew and ensure it is tidy and correctly coated with a launch agent to help in the simple elimination of the spreading. Inspecting the spreading for any kind of blemishes and making needed changes to the process will assist you enhance and ideal your light weight aluminum spreading method over time.

Devin Ratray Then & Now!

Devin Ratray Then & Now! Kenan Thompson Then & Now!

Kenan Thompson Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Justine Bateman Then & Now!

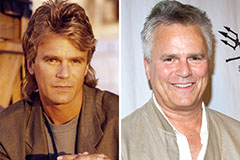

Justine Bateman Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!